Sheet Metal Fabrication

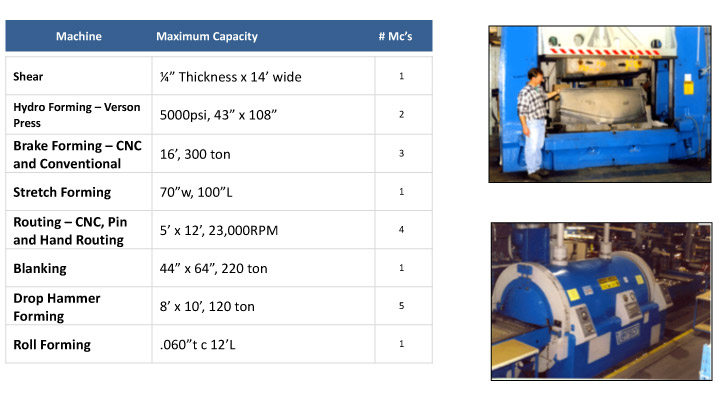

With a one-stop shop approach to fabrication, our sheet metal fabrication services cover several manufacturing capabilities, including brake forming, hydro forming, roll forming, and drop hammer forming.

Through the use of our sheet metal fabrication shop, IMP Aerostructures is able to perform spot welding on aluminum products that meet OEM specifications while standing as the primary supplier of drop hammer formed products in Canada.

Accreditations & Certificates

Approved to meet:

- Boeing Defence

- Lockheed

- Bell Helicopter

- Canadian Department of Defence

CNC Routing for tight tolerance requirements

IMP Aerostructures sheetmetal capabilites takes advantage of cost saving through the use of nesting software to maximize the utilization of raw materials and minimizing the cost of fabrication.

Extended capability at Forming Aluminum Products

IMP Aerostructures forming capabilities include High Pressure Forming of complex aluminum sheet products from small clips, webs and skins, to large beams up to 108” in length.

IMP’s sheetmetal fabrication includes many technologies

IMP Aerostructures has one of the largest Drop Hammer Forming facilities in North America. In addition, CNC Brake Form Presses, Stretch Forming of light extrusions, Stamping Presses and Impact Form Presses provide a complete in-house capability for fabrication of sheet metal parts.