Composite Bonding

IMP Aerostructures offers a wide range of processing capabilities that are designed to support in-house fabrication which reduce lead times, simply logistics and eliminate cost overruns.

Our NADCAP certified processes include:

- Composite Bonding

- Heat Treatment

- NDT

- Chemical Processing

Accreditations & Certificates

Approved to meet:

- Boeing Commercial

- Bombardier

- Bell Helicopter

- Lockheed

- Triumph

- Spirit Aerosystems

- Cessna

- L3 Crestview

- Sikorsky

- EADS Airbus

IMP Aerostructures Heat Treatment and Heat Aging

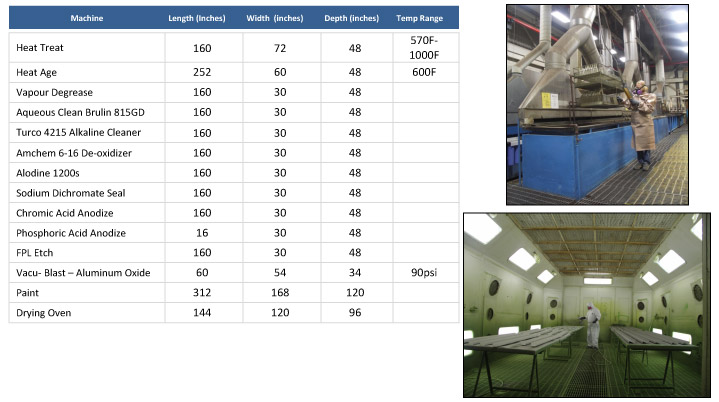

IMP Aerostructures processing line capabilities include Heat Treatment with Drop Down Furnaces, Salt baths and Heat Age Furnaces.

IMP Aerostructures Environmentally controlled Process Lines

IMP Aerostructures process lines include many of the Original Equipment Manufacturers process approvals include Chemical Conversion Coating, Alodine, Phosphoric Acid Anodizing, Boric Sulphuric Anodizing, Chromic Acid Anodizing, along with the required clean and degrease processes associated with processing of aluminum products.

IMP Aerostructures fabricates from “A to Z” on most products

IMP Aerostructures supports it’s “one stop shop” approach with the complete processing and painting of product under one roof, providing for minimum lead time on those urgent part requirements at a competitive cost, within the industry.